The fact that pumice is hygienic means it can be used as a raw material in toothpaste, dentures and dental prostheses. Pumice powder is a preferred material for tooth polishing powder. Its abrasive texture cleans tartar and plaque build-up on teeth and is effective in achieving a brighter appearance.

Pumice is used in a bleaching process known as abrasion. The edges of pumice are rounded off to avoid damage, then, it is used to wash denim to give it an old, used and worn appearance. Pumice also decolourises and soften the fabric.

Volcanic soil provides a suitable environment for growing plants thanks to supplementary nutrients provided by human and animal life, decaying plants and its own natural structure.

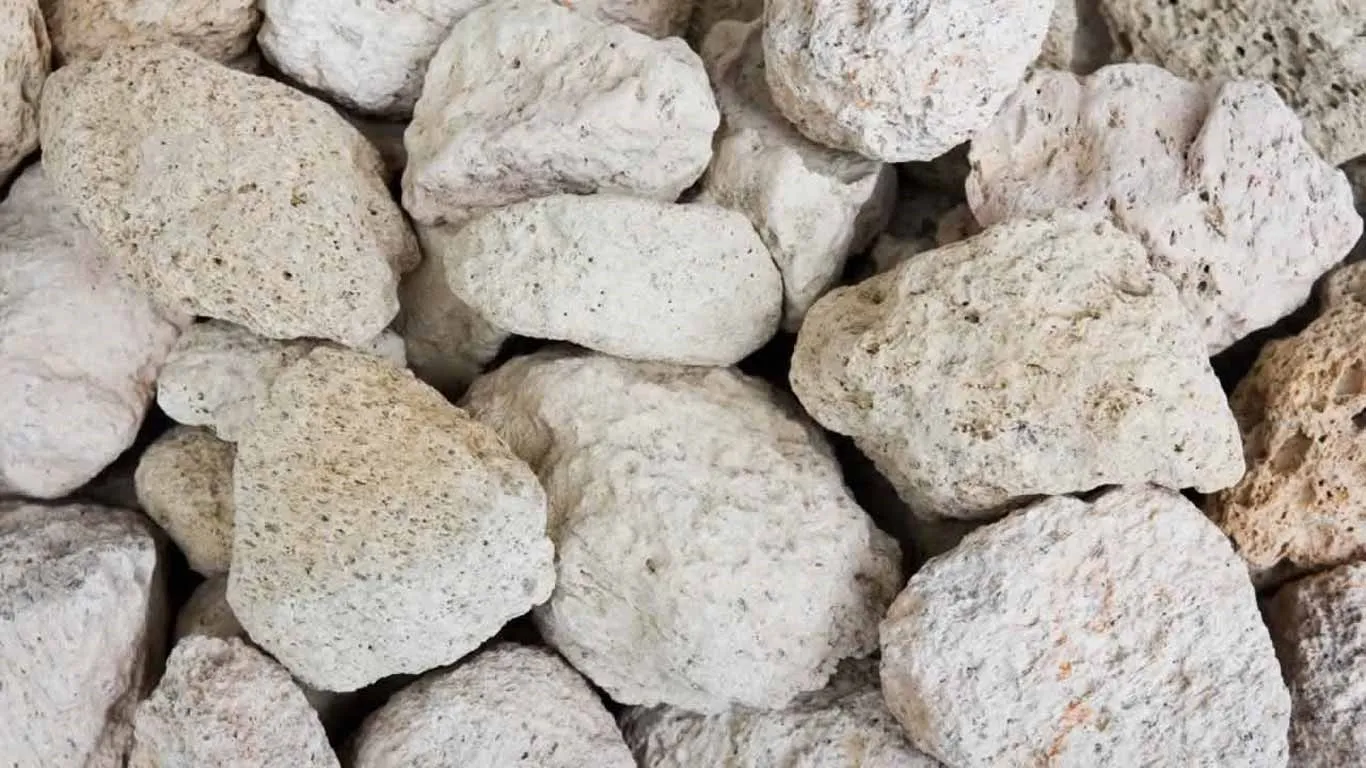

As a raw material, pumice is a natural hydroponics medium. The fact that pumice ore has a porosity of 85% means it has a lightweight density. Even the smallest unit of pumice ore has numerous small and large pores.

Pumice makes soil more porous and helps to ventilate the soil. It is also used as an excellent soil conditioner to regulate fertiliser feedings. Pumice is used as soil in greenhouses, areas in which bitter orange and fruits are grown, grass lawns and all types of agricultural areas. Moreover, its ability to retain moisture for long periods enables agriculture in arid soils. Pumice, at a certain depth and a certain thickness in the ground, retains and transmits moisture to plant roots according to the amount needed. It also keeps weeds from growing.

Pumice ExportationPumice accelerates plant development thanks to the minerals it contains and its porous structures helps to ventilate the soil. Therefore, drainage channels are not required for landscaping in which pumice is used and weeds do not present a problem.

Pumice has a density of up to 1/3 to 2/3 of normal sand and pebble. By using pumice stone mortar instead of sand cement mortar, less mechanical strength is used due to the lightness of the mortar. The use of lightweight construction products as filler and walling requires less concrete. It has the benefits of time and labour savings, because pumice concrete is lighter than common concrete in construction (specific bulk density is 800–900 kg/m3). This brings advantages related to time and labour and regular usage decreases building costs.

Moreover, gypsum, ceramic, etc. can be applied directly on the walls, these type of blocks are used in plaster, and after its application, cracking or blistering does not occur. It is earthquake resistant thanks to its elastic structure.

Pumice is not harmful to health, so it can be used to filter drinking water.

Pumice as a raw material can be used on the heels of feet. It does not cause any problems related to hygiene. Especially, heel stones made of pumice used for hells slough away the dead skin on heels.

Pumice is used in cleaning and polishing, to make vibrating materials, for electrical deposition and to clean mould.

It is used for its abrasive properties in polishing and to make motifs on picture frames.

Today many developed countries clean dirty facades with pumice stone instead of sand. Due to its soft abrasive features, pumice stone enables building surfaces to be cleaned without damaging them.